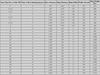

Description

Weld Backing / Chill Rings

- Available in Carbon Steel & 316L Stainless Steel

- Carbon Material: ASTM A109 ASME A414 Stamp

- Prices shown are for Schedule 40 Pipe

- Schedule 10 and Schedule 80 Pipe are available by request only

- Larger sizes are available by request

- Rings 14" or larger must be fabricated and ususally take 2-4 weeks

- Pipe Chart: Common Diameters & Wall Thicknesses PDF

Robvon "CCC" Backing Ring

Designed for quick easy joint alignment where the variation in inside diameters is relatively great.

Robvon Commercial Backing Rings are designed for quick, easy alignment of pipe, tube, fittings and valves and assure precise, close tolerance fit-up. They allow complete penetration and fusion of the weld and radiograph perfect certified welds.

The patented nubs automatically set the weld gap for the root-pass. The internal bevels and flat inner lands assure non-restricted fluid flow. The Robvon backing ring eliminates the necessity of tack welding and it also eliminates slag, icicles or metal inside the bore which create obstructions, which and can cause damage to valve seats and strainers when broken loose.

Backing Ring Welding Procedure

Robvon Backing Rings are inserted into the beveled pipe end with the spacer nubs flush against the pipe land and the ring gap positioned in the area of first bead deposition. The beveled end of the adjoining pipe is slipped onto the Robvon backing ring until the edge of the pipe land is firmly abutted against the spacer nub. Depending upon the Ring Style chosen, the welder has the choice of "striking off" the nubs or leaving them intact.

The welder can either weld the split making a solid ring or weld away from the split allowing the heat of the molten metal to expand the ring forcing it tightly against the inner surface of the pipe. This eliminates gaps, openings, or crevices between the Backing Ring and the pipe, tube, valve or fitting. Robvon engineered flat outer surfaces afford immediate access to the root of the weld and allow complete penetration. The 1/16" lands on the outer ring edges prevent curling. The internal bevels and flat inner land minimize flow turbulence on the downstream side to a nearly incalculable degree.

During welding, the arc should be directed as to penetrate the Robvon backing ring and inner edges of the pipe or fitting. The molten metal should penetrate into the Robvon Backing Ring approximately forty to fifty percent of the cross-sectional dimension thereby forming an integral welded joint.

STARTS AND STOPS OF THE WELD DEPOSIT AT THE "CC" LOCATIONS SHOULD BE AVOIDED IN THE ROOT PASS.

General Backing Ring Information

Backing Rings are manufactured with the following ring gaps included, but are not limited to, 3/32" or .030" on sizes 4" and smaller; 5" and larger exhibit a 1/8" or .040" gap.

Note: All rings are marked on inside diameter with Size, Sch, Heat No., Material Grade & Robvon Company Identifier